By BILL BRANDON

Germany is a recognized leader in renewable electricity. Their Energiewende law set ambitious goals for renewables but may be stalling out because of infrastructure insufficiencies. Germany curtailed 1581 gigawatt-hours of green energy in 2014. PV penetration levels are unsustainable with curtailment increasing an average of 100% every year. This curtailment only represents a small percentage of renewable energy, but still costs about US$94 million for undelivered electricity. This does not include planned curtailments in wind power. Distribution operators are projected to spend US$11.8 Billion over the next 10 years for grid optimization and high voltage transmission lines. This figure does not include funds from the 2009 Power Grid Expansion Act, which is expected to be 40% finished at the end of 2016. The government reports that energy storage is not likely to be the primary resource for grid balancing with demand management playing the greatest role.

Obviously just harvesting intermittent renewable energy is not enough for greening our energy sources. What can we learn from Germany? I was honored several weeks ago to be invited as an expert to a workshop on sustainable transportation sponsored by ASU and the New America Foundation. One topic of discussion was the integration of the transportation sector with the electrical sector. There were varied opinions on this, but a significant number did not believe that PEVs were the answer. While it might sound good, the devil is in the details. Some, like Mark Z. Jacobson, assert battery electric vehicles (BEV) are “the key transportation solution”. Although he is a respected researcher in climate and atmospheric modeling, he has often not shown much knowledge or foresight in his assumptions. I will address this issue shortly.

Just deploying BEVs does not guarantee they will be clean. The Dutch effort to push BEVs resulted in an increased need for coal generation. While one can rationalize a solution to this, changing human behavior to accomplish it is another thing. The Internet of Things will not necessarily change human behavior to the good. In addition, BEVs and FCEVs do not dovetail well with existing infrastructure and manufacturing capacity. Other options exist for integrating transportation with the electric grid. Primary among these is the production of hydrogen, although other pathways are being sought. (see https://www.nytimes.com/2016/05/03/science/carbon-dioxide-recycling.html?_r=2 Note ‘Electro Fuels’) The idea of using hydrogen to power fuel cell electric vehicles (FEV) has been around a long time, but starting up both a fuel side and a vehicle side simultaneously is a bit of a conundrum. Germany is experimenting with another approach by producing methane from waste CO2 and H2 produced from excess renewable power capacity. As noted in the New York Times article linked above, thermal chemical conversion of CO2 requires significant heat.

Storing electrons by producing H2, which is then attached to carbon, is a simple and elegant approach. It doesn’t need to be methane as it can be methanol, ethanol or hydrocarbons. Within the bioeconomy world, there are microbes that can do just that and more in a very efficient manner. Dr. Richard Kohn of the University of Maryland has isolated a microbe that can produce hexane, a hydrocarbon fuel molecule, using H2 and CO2. Of a more immediate commercial significance is a company that has come out of stealth mode, White Dog Labs. White Dog labs is a spin off from the University of Delaware and uses a ‘mixatrophic’ microbe that can not only ferment sugar, but also in the presence of hydrogen will also ferment the CO2 that is developed in the ‘beer’. This microbe can be inserted into existing bio-refineries with little added cost and double ethanol output from any existing sugar input, either from corn or cellulosic corn stover. See https://www.biofuelsdigest.com/bdigest/2016/06/13/50-yield-boost-for-ethanol-no-co2-what-white-dog-labs-comes-out-of-stealth/

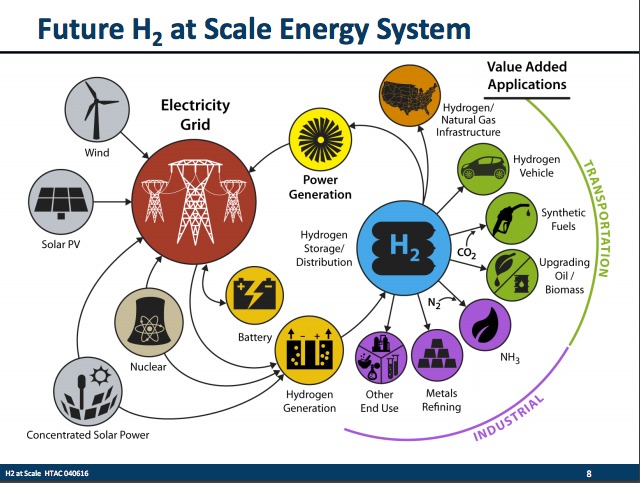

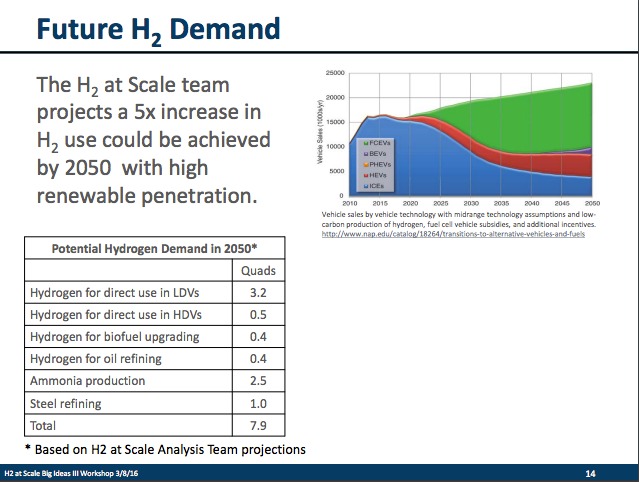

While these technologies have been developed in Washington DC’s back yard, DoE seems to be totally oblivious to these promising bio-processing approaches. DoE has recognized the need to integrate excess renewable power with transportation, but assumes approaches that are demonstrably less efficient than bio-processes or production of liquid fuels. Here is a presentation from DoE of the future of H2 at scale https://www.hydrogen.energy.gov/pdfs/htac_apr16_10_pivovar.pdf Below are two slides showing H2 uses and where they think the Demand for H2 will be.

You will note that production of low carbon liquid fuel is not even included in this chart, while H2 fuel cell vehicles are given a large portion of the demand.

The simplicity of storing and transporting a liquid fuel cannot be ignored. It can also be more efficient. It doesn’t need to be compressed and stored in robust tanks. Liquid fuels are beautifully simple. So let’s look at efficiency.

Some people believe that BEVs will become a wide spread means of transportation; others think they will only have a limited use market. An understanding of the fundamentals of battery storage is necessary to understand the limitations of BEVs. When charging or discharging a battery, heat is created. The amount of heat depends on the rate of charging or discharging. Batteries for vehicles have a built-in cooling system. When charging or discharging at high rates this cooling system requires active cooling (like an air conditioner) that requires power to operate. This is why electron-to-electron energy storage is often not efficient. If a BEV is charged at night with renewable electricity from a PV array, this inefficiency is increased, as energy must be first collected using something like an Elon Musk ‘power wall’. It is then discharged to charge the BEV battery before it is discharged for vehicle use. This method of charging small cars being driven only 35 – 50 miles per day may be acceptable but limits the use of the car. If vehicles are used more than this and especially for longer trips over 200 miles the charge cycle becomes an issue. Either trips must be interrupted for long charging times or battery charging efficiency really drops with fast charging.

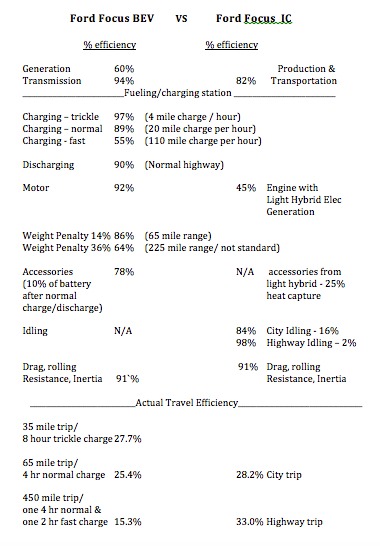

The following table compares a Ford Focus BEV with a Ford Focus with an IC engine. It is a forward looking comparison using presently existing technologies not necessarily commercially deployed. It also assumes increased accessory draw required by more sensors and potential auto-drive technology. The BEV has a 23 KW battery or a theoretically expanded 70 KW battery similar to a Tesla. The I4, 1.6 liter engine is similar to the Ford Eco Boost turbocharged available today except optimized for a 100 RON fuel with a 1400 BTU/Gallon latent heat of evaporation (E30 or equivalent). It is also assumed that it is a light hybrid where a battery is charged using waste heat similar to a system developed by Ricardo. Weight and range information is from Ford Motor Company. Weight penalties are from a Ricardo light weighting report from 2008. Battery charge/discharge information is hard to get from OEMs. I have relied on information obtained from a Tesla owners chat room and other basic scientific battery data. Electrical generation efficiencies are the best presently under development (combined cycle gas or Allum cycle gas generation). The fuel production and delivery is a standard figure that might be a bit high, depending on geography.

From the table it is apparent that a modern IC engine with a modern high octane fuel can compete with a BEV on short trip efficiency and significantly out perform a BEV for longer trips. This analysis is based on total thermal efficiency only. GHG emissions are another, more complicated, matter. Generation from a 60% efficient gas generator is only a technical possibility now being demonstrated and other sources of traditional generation would result in a significantly larger carbon footprint. Electrical generation from a renewable source is a possibility, but sufficient development for a meaningful impact on transportation is a long way off and in the mean time applying those technologies to green the grid will be more efficient and more impactful if excess capacity is used to produce H2. Low carbon fuels, on the other hand, already comprise over 10% of road transportation fuels and the technology is available to rapidly expand their market share.

This analysis applies only to BEV vehicles. Fuel cell electric (FEV) vehicles are better, but the weight of a robust compressed hydrogen fuel tank and fuel cell will also carry a weight penalty. Energy necessary to compress hydrogen and present moderate efficiencies from fuel cells will also lower efficiencies. Assuming generation from a renewable electric source, total efficiencies might be about 31% – 38%.

A forward thinking review might suggest that hydrogen production could be a better interface with the electric grid. It could be a variable demand source taking excess capacity at varying times unconnected to drive convenience and leveling the grid balance. This would particularly apply to wind energy where production costs are already low and there is significant excess capacity potential.

Hydrogen production as a buffer method for the grid is a flexible platform that can be used in three ways:

1) It can be a second or third tier of grid resilience because it or produced liquid fuel can be used to produce electricity.

2) It can be used as hydrogen for transportation fuel cells.

3) It can be combined with waste CO2 to make liquid fuels.

This third use is often neglected or not known. Liquid fuels are advantaged because they are easy to store or transport with a low cost and energy efficient infrastructure. They may also prove to be a less costly way to modernize the grid, provide resilience and utilize intermittent renewable capacity.

Is hydrogen from electrolysis a reasonable proposition? I think so; we just need cheap electricity. In terms of renewable electricity, wind power is the most challenged for matching production with demand. Nocturnal wind is strong at a time when demand is at its lowest. There have been times when wind power providers could not ‘trim’ their turbines enough and had to PAY the grid to take their electrons.

Iowa not only leads the states in 1st gen ethanol production, but is also 2nd to Texas in total gigawatts of wind power. It is 1st in percentage of power supplied by wind (31.3%), followed by South Dakota, Kansas, Oklahoma, North Dakota and Minnesota i.e. the Midwest corn belt. (Nebraska needs to step up its game!) Let’s look at Iowa, a state with good policies to promote sustainable energy.

Last year Iowa produced 17,878 gigawatt hours (GWh) of wind power operating at 34% of installed capacity. Of the 66% of curtailed capacity about 13% is attributed to seasonal wind variations. The remaining 53% of curtailment is due to diurnal variances and lack of demand. Lets assume that 2/3 of this curtailment was due to lack of wind, leaving about 9200GWh per year curtailed due to lack of demand but still available, basically at night in the early morning hours. It takes 39 KWh to produce 1 kg of hydrogen. During this window, 9200 GWh could produce 235,000 metric tons of hydrogen per year. This is enough hydrogen to utilize White Dog Lab’s mixotrophic technology in 66% of all ethanol refineries in the state and produce another 1.3 billion gallons of ethanol in Iowa. Closer analysis might prove these estimates conservative. In addition, oxygen will be produced as a co-product, which will have some market value. It could also be used in a process like Sierra Energy’s Fast-Ox gasification.

What about cost? Recent PPA’s for wind in Iowa were about $22/MWh or $.022/ KWh. Purchasers able to provide demand response and take power at night levelizing the power demand could buy wholesale somewhere between $0 – $.022/ KWh, lets say a penny a KWh+ transmission fees for underused infrastructure. $.39 for basic power + capital and operating costs could bring Hydrogen in at close to the $1.00/ kg. When combined with CO2 that presently is vented can provide for a good margin for production compared to present low oil prices.

What about water usage? The mixothrophic process actually creates some water that can be used in the refining process. Water for electrolysis however does not need to be ‘fresh’. Brackish water is actually preferred for hydrogen electrolysis and is generally available in the Midwest. The US Geological Survey is presently conducting the National Brackish Groundwater Assessment to provide greater knowledge about this resource. Electrolysis of water into hydrogen would require about 1/2 gallon of water per gallon of additional ethanol produced and half of this would be returned to the refining process. Current water usage in ethanol production is about 3 gallons per gallon of ethanol and water for petroleum is significantly higher than that.

1st gen ethanol refineries are batch processes taking about 2 days to complete. It is conceivable that hydrogen production could be immediately stored in the fermentation vat at the times that power is available. It is not my purpose here to provide a complete solution, but to broaden perspectives to what might be possible. Wind power in the Midwest is outpacing the infrastructure and its ability to completely use wind power’s production capacity. A mixotroph may be able to make first gen ethanol refineries more efficient, but it may also be able to also make wind power more efficient. Lower and more competitive prices depend on maximizing efficiencies within our industrial ecosystem. Dr Tracy Of White Dog Labs states “The bioeconomy may never come to massive scale fruition for petrochemical replacement unless you’re able to marry up an approach where you get energy into a sugar fermentation. That is the missing link.” This ‘missing link’ may very well require integration with the electrical grid.

A related discussion can be found here:

Leave a Reply